Understanding the fuel type (gas, electric, propane, solar) is key to assessing heater installation complexity. Each fuel type has unique requirements for venting, power sources, tools, space, and safety permits, impacting overall installation difficulty. Proper evaluation ensures safe, efficient heater setup tailored to specific fuel type needs.

When evaluating a heater’s installation complexity, understanding the fuel type is crucial. This guide breaks down the process for gas, electric, and alternative fuel heaters, highlighting key considerations like installation requirements, space constraints, and safety aspects including permits and ventilation. By assessing these factors, you can ensure a smooth and safe heating solution tailored to your needs.

- Assess Fuel Type: Gas, Electric, or Alternative?

- Understand Installation Requirements and Tools

- Evaluate Space Constraints and Accessibility

- Safety Considerations: Permits, Ventilation, and Maintenance

Assess Fuel Type: Gas, Electric, or Alternative?

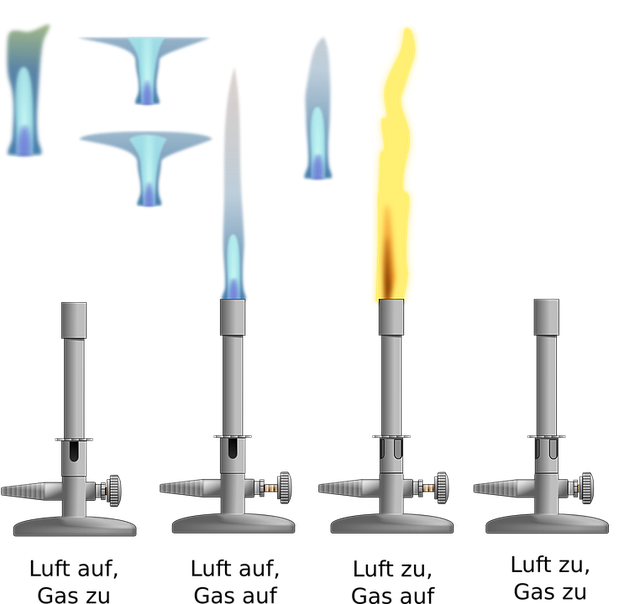

When evaluating the installation complexity of a heater, assessing the fuel type is a crucial first step. Heaters can run on gas, electric, or alternative fuels like propane or solar energy. Each fuel type has its unique considerations and installation requirements. For instance, gas heaters require proper venting and a connection to a gas line, which might necessitate additional plumbing work. Electric heaters, on the other hand, need a stable power source and suitable wiring, ensuring safety and efficiency.

Alternative fuel heaters, such as those using propane or solar energy, have their own set of installation complexities. Propane heaters need storage tanks and reliable delivery systems, while solar heaters demand strategic placement for optimal sunlight exposure. Understanding these variations in fuel type is essential to accurately gauge the overall installation complexity and prepare for any specialized tasks or requirements.

Understand Installation Requirements and Tools

Before evaluating the installation complexity of a heater, it’s crucial to understand the specific requirements and tools needed for the job. The complexity varies greatly depending on the fuel type – be it electricity, gas, propane, or oil – each requiring different setup processes and hardware. For instance, electric heaters often involve installing new circuits and outlets, while gas heaters necessitate piping installations and gas line connections that demand specialized knowledge and equipment.

Additionally, various tools are required for successful installation, from basic hand tools like wrenches and pliers to more advanced power tools such as drills and saws. Understanding these upfront not only ensures you’re prepared but also helps in accurately assessing whether the project aligns with your skill level or requires professional assistance.

Evaluate Space Constraints and Accessibility

Evaluating space constraints and accessibility is a critical step in determining the installation complexity of a heater, especially considering the diverse fuel types available. Different heaters have varying requirements regarding the physical area they need to function optimally. For instance, a gas heater might require adequate ventilation and easy access to its control panels, while an electric heater could demand specific electrical connections and outlet placement.

When assessing space, take into account the heater’s size, the surrounding environment, and any potential obstacles. In confined spaces, certain types of heaters may not be feasible or could require additional installation considerations. Accessibility is also key; ensuring that maintenance and future repairs can be conducted efficiently will help streamline the overall installation process and contribute to better long-term performance, regardless of the fuel type.

Safety Considerations: Permits, Ventilation, and Maintenance

When evaluating the installation complexity of a heater, it’s crucial to consider several safety aspects. Firstly, ensure compliance with local building codes and regulations by obtaining necessary permits before starting any installation work. This step is essential to avoid legal issues and potential hazards. Different fuel types, such as natural gas, electricity, or propane, may have distinct permit requirements, so consult your local authorities for specific guidelines.

Proper ventilation is another critical factor. Heaters, especially those using fossil fuels like natural gas or propane, require adequate airflow to prevent the buildup of harmful gases, including carbon monoxide. Inadequate ventilation can lead to asphyxiation or poisoning. Regular maintenance, including cleaning and inspecting vents, filters, and exhaust systems, ensures optimal safety and efficiency. This proactive approach helps maintain a healthy indoor environment and prevents potential disasters related to fuel type-specific hazards.